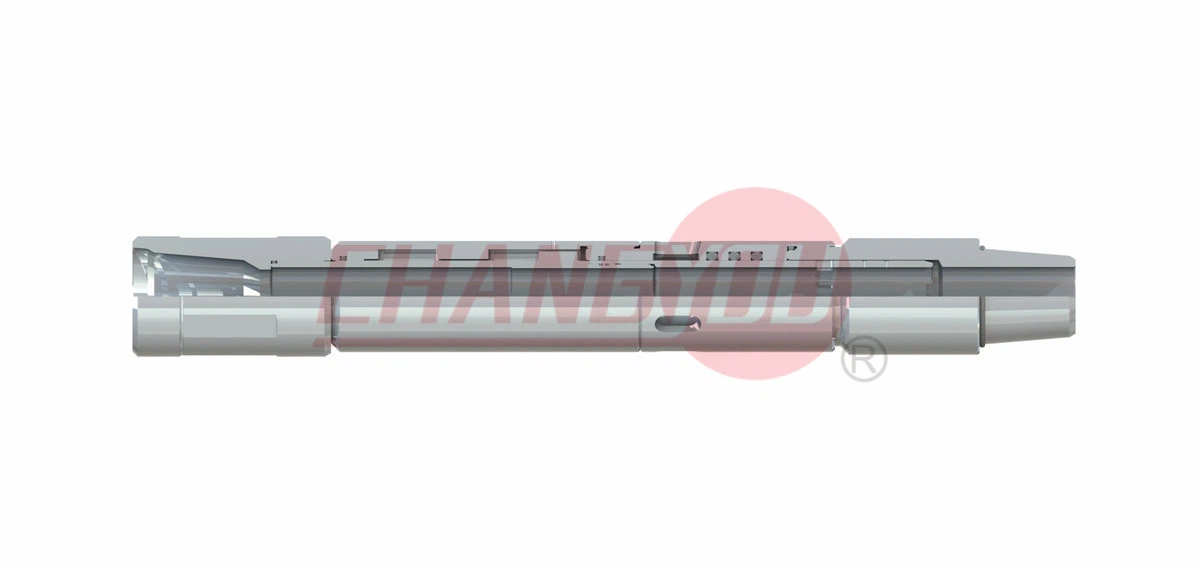

The Non-Rotating Champ Packer is ideal for deepwater extended reach applications on floating vessels, where

vessel heave and obtaining sufficient torque down hole to manipulate the toolstring can be a major challenge or for highly deviated wells. This packer has the same basic features that it does not require rotation to set and can be re-set for a predetermined number of times.

It is a hookwall retrievable packer with a concentric bypass and a continuous indexing J- slot which incorporates a lock-out mechanism. The non rotating champ packer can cycle from the run-in-hole (RIH) position to the set and pull-out-of-hole (POOH) position simply by lifting or lowering the workstring in the wellbore. After the packer has been set the required amount of times, the packer can be mechanically locked out to prevent any further setting operations as the toolstring is recovered from the wellbore.

Each assembly includes an indexing lock-out J-slot mechanism, mechanical slips, packer elements, hydraulic

slips, and a concentric bypass. Round, hydraulic piston-type slips in the hydraulic holddown mechanism

prevent the packer from being pumped up hole.

A J-slot position locking mechanism keeps the packer in the RIH configuration until the desired depth is

reached and the locking mechanism is deactivated. The position locking mechanism is deactivated by the use

of a rupture disk, which is set to rupture at a pressure that is predetermined during the job calculations. The

deactivation pressure can be either wellbore hydrostatic at a predetermined depth or pump pressure applied to

the wellbore at surface. The locking mechanism allows the packer to be run without cycling through the

positions in the J-slot as each joint of pipe is being made up at the surface.

The J-slot lock-out mechanism prevents the packer from setting after the operation is complete and allows the

string to move freely even in significant heave situations on floating vessels.

| Sizes | 4 1/2"-13 3/8" |

| Working pressure | 15k |

| Working temp | 400℉ |

| Connections | CAS/IF/EUE and others |

Your Professional Cased Hole Dst Tools Supplier

Baoji Changyou Petroleum Equipment Co., Ltd. specializes in the design, manufacture, and sales of oilfield drilling equipment, surface testing equipment, downhole well and formation testing equipment (including drill stem test/DST tools: mechanical and pressure control), and exploration equipment. Additionally, we provide research and development (R&D) services to clients with specific requirements.

Professional Team

Our technical department comprises over 10 highly skilled R&D personnel who possess extensive design expertise, practical experience, and field testing capabilities.

01

Advanced Equipment

The company is equipped with a wide range of testing and machinery processing equipment, enabling comprehensive inspection, testing, and processing capabilities.

02

Independent Intellectual Property Patents

As a professional equipment manufacturer, Changyou holds numerous patents with independent intellectual property rights, providing robust technical support to our clients.

03

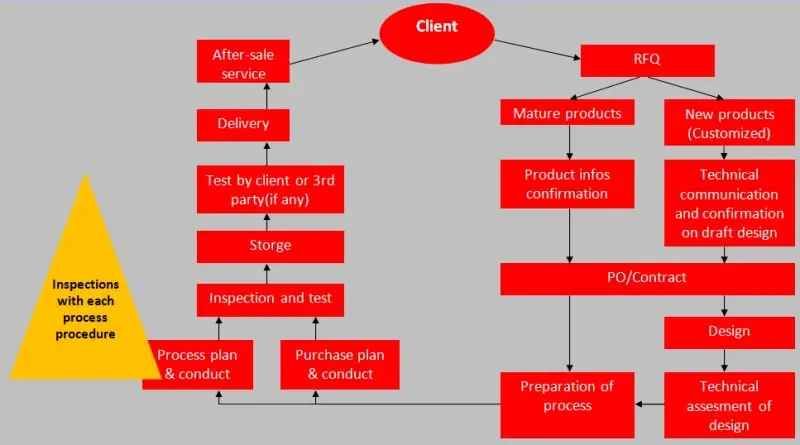

Strict and Reliable Quality Control (QC) System

Each component undergoes rigorous inspections at every stage of production. We also welcome third-party inspections and certifications, such as those from SGS and BV.

04

Specification of Cased Hole Dst Tools

|

Sizes |

6 3/8" |

4 1/2"-13 3/8" |

3 7/8", 5" |

3 7/8"-9 5/8" |

|

Working pressure |

10k |

10k |

15k |

15k |

|

Working temp |

400℉ |

400℉ |

400℉ |

400℉ |

|

Connections |

CAS/IF/EUE and others |

CAS/IF/EUE and others |

CAS/IF/EUE and others |

CAS/IF/EUE and others |

Types of Cased Hole Dst Tools

Storm Valve

The storm valve is used to close the well being drilled, but does not need to pull the drill pipe out of the borehole. This feature is particularly suitable for offshore drilling operations.

HP Surge Valve

The HP surge valve is a full opening annulus pressure operated valve for cased wells. The tool normally operates as a back pressure valve. The valve consists of two sections: the ball valve section and the working piston section.

Shear Pin Circulating Valve

In the cased well testing, the shear pin type reverse circulating valve is a special joint, which is equipped with a circulating pin and an O-ring.

Pump Out Circulating Valve

The pump out reverse circulating valve is a circulating valve opened with the help of external force after the test. After the pump out reverse circulating valve is opened, the reverse circulating can be carried out, and the circulating can also be carried out.

Applications of Cased Hole Dst Tools

Identifying reservoir fluids: Cased hole dst tools tools can help determine the type of fluids (oil, gas, water) present in the reservoir.

Assessing wellbore damage: Cased hole dst tools can help identify and quantify any damage to the wellbore that may be affecting production.

Evaluating reservoir saturation: Cased hole dst tools can help determine the amount of oil, gas, and water present in the reservoir.

Determining flow profiles: Cased hole dst tools can help determine where fluids are flowing within the reservoir.

Assessing well integrity: Cased hole dst tools can help ensure the well is properly sealed and that there are no leaks.

Optimizing perforating and completion programs: Cased hole dst tools data can be used to optimize the placement of perforations and the type of completion used in the well.

Safety Considerations for Cased Hole Dst Tools Testing

● Before any drill stem test, conduct a safety meeting of all personnel participating in the test. Discuss safety factors, wind direction and exits.

● Ask the well service company representative about any possible hazards that could arise during the test.

● Check BOP and choke lines to see that they are not plugged and are tied down properly.

● Be sure the derrick auxiliary escape device is installed and working properly.

● Be sure that the drilling mud is properly conditioned.

● Be sure that the fill-up lines are installed on the drilling nipple above the BOP to keep hole full of mud.

● See that the cellar is jetted if no drain is available.

● Check the water connections on the spray manifold.

Be used in a wide range of industries.

First we discuss order details, production details by email or TM.

Then we issue you an PI for your confirmation.

You will be requested to do pr-epaid full payment or deposit before we go into production.

After we get the deposit, we start to process the order. We usually need 7-15days if we don’t have the items in stock.

Before production has been finished, we will contact you for shipment details, and the balance payment.

After payment has been settled, we start to prepare the shipment for you.

Packaging and Shipping

|

Packaging |

Wooden box Or customized according to customer requirements |

|

Shipping |

We will help you to choose the best shipping way according to your detail requirements. By sea, by air, or by express, etc. |

Inspection Facilities

|

|

|

|

|

|

QC Flow Chart

FAQ

Q: What are the main functions of cased hole DST toolsss?

A: Its main functions include establishing test conditions in cased holes, collecting reservoir fluid samples, measuring parameters such as reservoir pressure and permeability, and evaluating the potential production capacity and economic value of the well.

Q: What components do cased hole DST toolss usually consist of?

A: Cased hole DST toolss usually consist of packers, valves, pressure gauges, and other analytical tools. Packers are used to isolate the test area, valves are used to control fluid flow, and pressure gauges are used to measure reservoir pressure.

Q: What is the difference between cased hole DST toolss and Open Hole DST Tools?

A: The main difference lies in the application environment and test method. cased hole DST toolss are used in cased wells, while Open Hole DST Tools are used in uncased open hole wells. In addition, cased hole drill stem test tools may need to adapt to more complex wellbore environments, such as higher pressures and temperatures, and more complex fluid compositions.

Q: What are the advantages of cased hole DST toolss?

A: The advantages include the ability to accurately collect reservoir data in cased holes, evaluate well production potential, improve testing efficiency, and reduce testing costs. In addition, these tools have high reliability and durability and can work for a long time in harsh wellbore environments.

Q: How to choose the right cased hole DST toolss?

A: Selecting the right cased hole DST toolss requires consideration of multiple factors, including wellbore environment, test objectives, budget, etc. Operators should select tools with appropriate specifications and functions according to the specific situation and ensure that they comply with relevant safety standards and regulations.

Q: How to improve the test accuracy of Cased Hole DST?

A: Improving the test accuracy of Cased Hole DST requires multiple aspects. First, the accuracy and reliability of the test equipment should be ensured; second, appropriate test methods and parameters should be selected; finally, the analysis and interpretation of test data should be strengthened to draw more accurate conclusions.

As one of the most professional cased hole dst tools manufacturers and suppliers in China, we're featured by quality products and competitive price. Please rest assured to buy high-grade cased hole dst tools in stock here from our factory. Contact us for customized service.