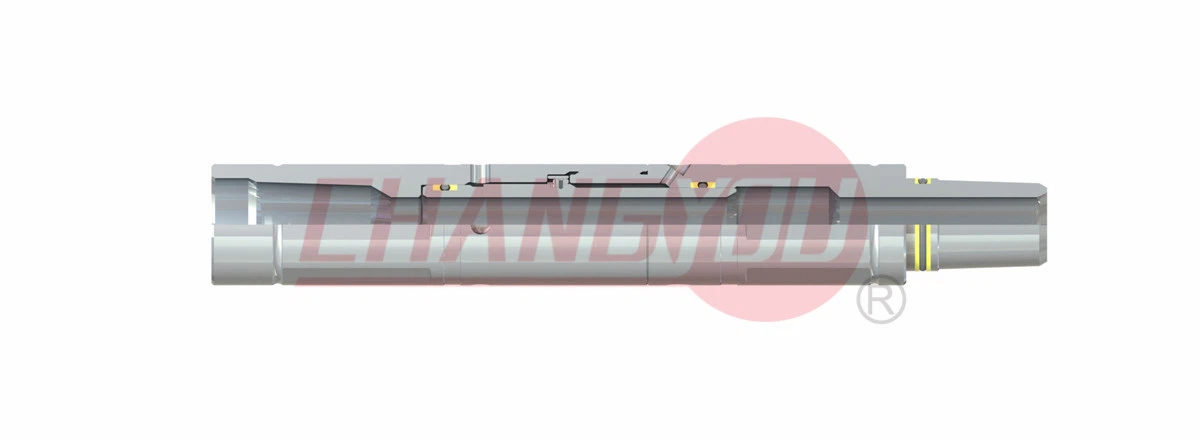

It is a kind of hydraulic setting, permanent completion packer used in casedhole. It has the function of releasing and re-attach, the parts above the packer in the string can be retrieved , maintained or replaced, after releasing, the double-way mechanical slips and inner lock mechanism can insure the packer stable,suitable for single shot completion operation.

| Sizes | 5"-9 5/8" |

| Working pressure | 15k |

| Working temp | 400℉ |

| Connections | CAS/IF/EUE and others |

Your Professional Completion Packers Supplier

Baoji Changyou Petroleum Equipment Co., Ltd. specializes in the design, manufacture, and sales of oilfield drilling equipment, surface testing equipment, downhole well and formation testing equipment (including drill stem test/DST tools: mechanical and pressure control), and exploration equipment. Additionally, we provide research and development (R&D) services to clients with specific requirements.

Professional Team

Our technical department comprises over 10 highly skilled R&D personnel who possess extensive design expertise, practical experience, and field testing capabilities.

01

Advanced Equipment

The company is equipped with a wide range of testing and machinery processing equipment, enabling comprehensive inspection, testing, and processing capabilities.

02

Independent Intellectual Property Patents

As a professional equipment manufacturer, Changyou holds numerous patents with independent intellectual property rights, providing robust technical support to our clients.

03

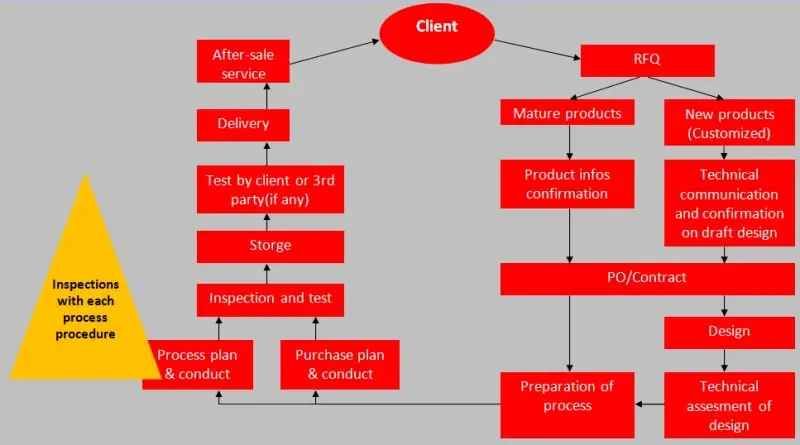

Strict and Reliable Quality Control (QC) System

Each component undergoes rigorous inspections at every stage of production. We also welcome third-party inspections and certifications, such as those from SGS and BV.

04

Specification of Completion Packers

|

Sizes |

5"-9 5/8" |

6 5/8"-9 5/8" |

|

Working pressure |

15k |

10k |

|

Working temp |

400℉ |

400℉ |

|

Connections |

CAS/IF/EUE and others |

CAS/IF/EUE and others |

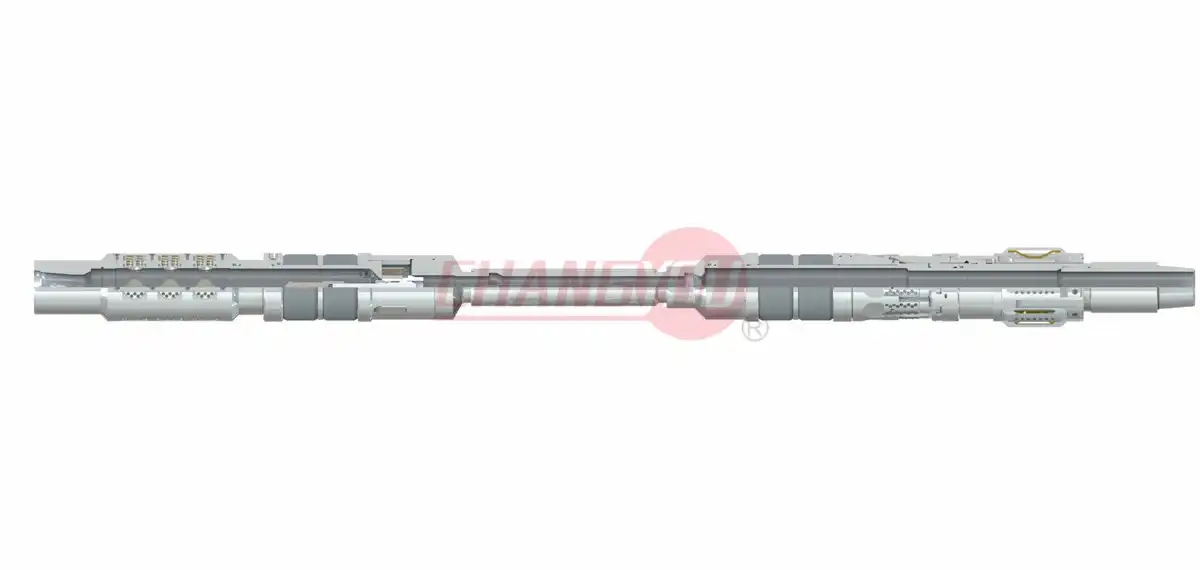

Types of Open Hole Dst Tools

The open hole dst tools produced by our company mainly include the following types:

Hydraulic Packers

A hydraulic packer serves best for well-completion jobs where production is applicable. This packer is unique because operators will use deliberate and specified hydraulic pressure to set the packer instead of using force on the tubing string. The applied hydraulic pressure is a piston and can firmly adhere the set to a casing. The lack of movement during the setting is relatively advantageous for various applications, especially in instances with multiple packers.

ESD Packer

An ESD packer refers to an Emergency Shutdown (ESD) packer. It is a specialized type of packer designed to provide a rapid and reliable means of shutting off the flow of fluids in the event of an emergency or abnormal situation. ESD packers are primarily used in well control and safety systems to prevent uncontrolled releases of hydrocarbons and maintain wellbore integrity.

Key Features of Completion Packers

Constructed from high-grade materials to withstand pressure and temperature extremes.

Advanced design and materials ensure a tight seal, preventing fluid migration and maintaining pressure integrity.

Resistant to the corrosive environments common in oil and gas wells, ensuring long-term functionality.

Functions of Completion Packers

● Prevent downhole movement of the tubing string, generating considerable axial tension or compression loads on the tubing string.

● Support some of the weight of the tubing where there is significant compressive load on the tubing string.

● Allows the optimum size of well flow conduit (the tubing string) to meet the designed production or injection flow rates.

● Protect the production casing (inner casing string) from corrosion from produced fluids and high pressures.

● Can provide a means of separating multiple producing zones.

● Hold well-servicing fluid (kill fluids, packer fluids) in the casing annulus.

● Facilitate artificial lift, such as continuous gas lifting through the A-annulus.

Completion Packer Operation, Setup Procedures and Spacing Considerations

Very deep set capability. Situations requiring production packers to be set very deep (12,000 feet/3,658m +) indicate the need for setting mechanisms that are not dependent on tubing manipulation, namely the hydraulic and electric line set packers.

Packer setting procedure without pump or electric line unit-(mechanical set). At times it is necessary to utilize a specific packer setting mechanism because the associated support equipment is not available to accomplish the setting operation by some other means.

Setting on the pipe without tubing manipulation-(hydraulic set). If electric line set capability is not available for some reason and hole conditions or pipe handling equipment makes tubing manipulation difficult or impossible, hydraulic setting is the remaining choice.

Run and set the packer quickly and accurately-(wireline set). It is sometimes desirable or necessary to be able to run and set a packer as quickly and accurately as possible. In these cases, the need is often related to another need – the need to plug the well. The electric line set packers, whether permanent or retrievable, are considered most appropriate.

The packer hydraulic setting procedure with low set pressure-(large setting piston area). At times it is necessary to be able to hydraulically set a packer using lower pump pressure because of surface or downhole support equipment or completion equipment pressure limitations.

Multiple set/release on same trip-(mechanical-set retrievable). Many times well conditions and operational goals make it necessary to run a packer that can be set and released multiple times. Several different packer design features are necessary for this capability.

Retrievable bridge plug capability, bi-directional pressure, tubing and packer retrievable. The capability to use a production packer as a retrievable bridge plug is desirable in many different completion situations. Basically, this capability simply means the packer can be left in the hole in a plugged condition (tubing is retrieved separately).

Permanent bridge plug capability, bidirectional pressure, permanent packer. The same basic criteria apply to permanent bridge plug capability as with retrievable but without the packer retrievability requirement. Also, the accessory plugging equipment is essentially the same.

Order Process

● First we discuss order details, production details by email or TM.

● Then we issue you an PI for your confirmation.

● You will be requested to do pr-epaid full payment or deposit before we go into production.

● After we get the deposit, we start to process the order. We usually need 7-15days if we don’t have the items in stock.

● Before production has been finished, we will contact you for shipment details, and the balance payment.

● After payment has been settled, we start to prepare the shipment for you.

Packaging and Shipping

|

Packaging |

Wooden box Or customized according to customer requirements |

|

Shipping |

We will help you to choose the best shipping way according to your detail requirements. By sea, by air, or by express, etc. |

Inspection Facilities

|

|

|

|

|

|

QC Flow Chart

Q: What are completion packers?

A: Completion packers are devices used in the oil and gas industry to manage downhole risks with robust sealing technology. They enhance completion integrity and longevity and are designed to meet specific wellbore or reservoir conditions.

Q: How do completion packers work?

A: Completion packers work by creating a seal between the casing and the wellbore. They can be set mechanically, hydraulically, or by other means to isolate specific zones and control fluid flow.

Q: How are completion packers installed?

A: Completion packers are typically installed during the completion phase of a well. They can be run in on wireline, coiled tubing, or drill pipe, depending on the specific application and wellbore conditions.

Q: What is the difference between completion packers and other wellbore sealing devices?

A: Completion packers are specifically designed for use in the completion phase of a well and are typically more sophisticated and customizable than other wellbore sealing devices. They are also subject to stricter quality and safety standards.

Q: Can Completion Packers be used in horizontal wells?

A: Yes, Completion Packers can be used in horizontal wells. However, special considerations may be required to ensure proper installation and sealing in these complex wellbore geometries.

Q: What is the life expectancy of Completion Packers?

A: The life expectancy of Completion Packers can vary depending on factors such as wellbore conditions, fluid properties, and the specific type of packer used. Proper maintenance and inspection can help to extend their useful life.

As one of the most professional completion packers manufacturers and suppliers in China, we're featured by quality products and competitive price. Please rest assured to buy high-grade completion packers in stock here from our factory. Contact us for customized service.