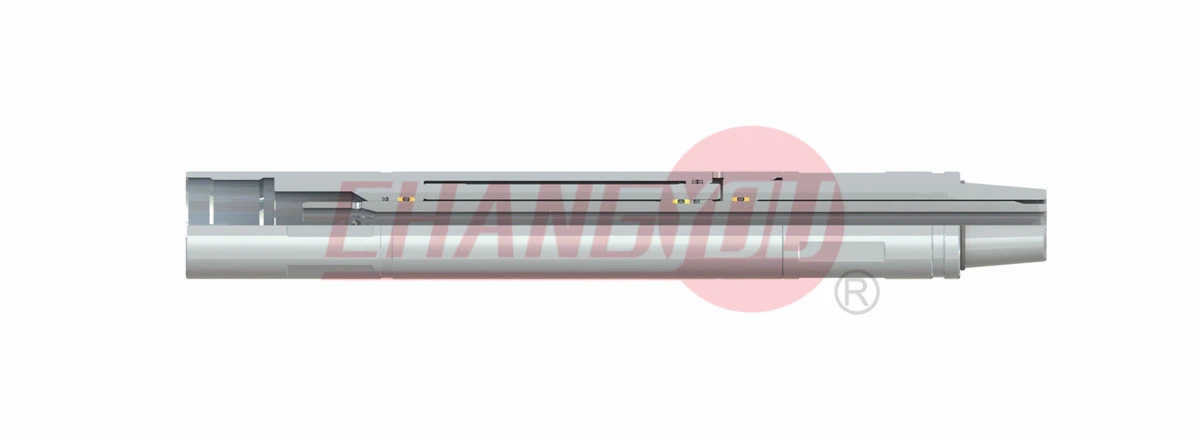

The full bore mechanical tester valve is a tool for opening and closing the well by lifting and lowering the drill pipe (or tubing) to control the ball valve of the tester valve. The tester valve is closed while the tool is running in hole. When the tool reached the predetermined depth, J-slot mandrel will move up and down by applying the weight of workstring, and the transposition lug can rotate freely, then it will move along the travel of index groove. The workstring is lifted or set down one time, the position of J-slot mandrel will change one time, like this, the ball valve can be opened and closed finally. Above movement can be repeated many times as required.

| Sizes | 3 7/8", 5" |

| Working pressure | 15k |

| Working temp | 400℉ |

| Connections | CAS/IF/EUE and others |

Your Professional Open Hole Dst Tools Supplier

Baoji Changyou Petroleum Equipment Co., Ltd. specializes in the design, manufacture, and sales of oilfield drilling equipment, surface testing equipment, downhole well and formation testing equipment (including drill stem test/DST tools: mechanical and pressure control), and exploration equipment. Additionally, we provide research and development (R&D) services to clients with specific requirements.

Professional Team

Our technical department comprises over 10 highly skilled R&D personnel who possess extensive design expertise, practical experience, and field testing capabilities.

01

Advanced Equipment

The company is equipped with a wide range of testing and machinery processing equipment, enabling comprehensive inspection, testing, and processing capabilities.

02

Independent Intellectual Property Patents

As a professional equipment manufacturer, Changyou holds numerous patents with independent intellectual property rights, providing robust technical support to our clients.

03

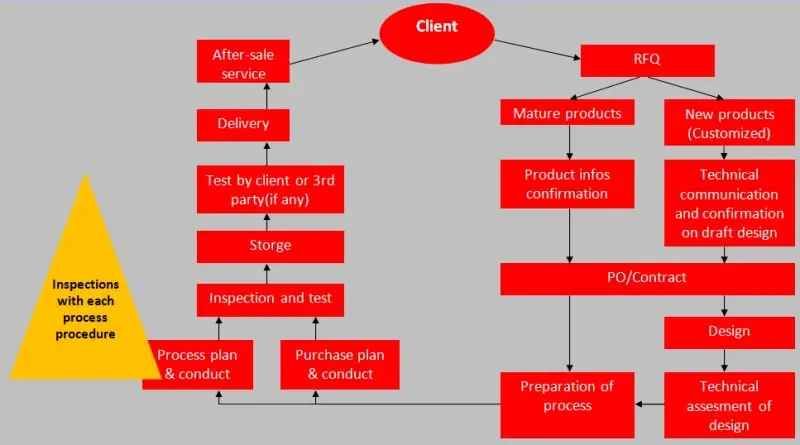

Strict and Reliable Quality Control (QC) System

Each component undergoes rigorous inspections at every stage of production. We also welcome third-party inspections and certifications, such as those from SGS and BV.

04

Specification of Open Hole Dst Tools

|

Sizes |

3 7/8", 5" |

7 5/8″-11 1/2″ |

4 3/4" |

5" |

|

Working pressure |

15k |

195-249 mm |

10k |

10k |

|

Working temp |

400℉ |

400℉ |

400℉ |

400℉ |

|

Connections |

CAS/IF/EUE and others |

FH and others |

CAS/IF/EUE and others |

CAS/IF/EUE and others |

Types of Open Hole Dst Tools

The open hole dst tools produced by our company mainly include the following types:

Openhole Hydraulic Jar

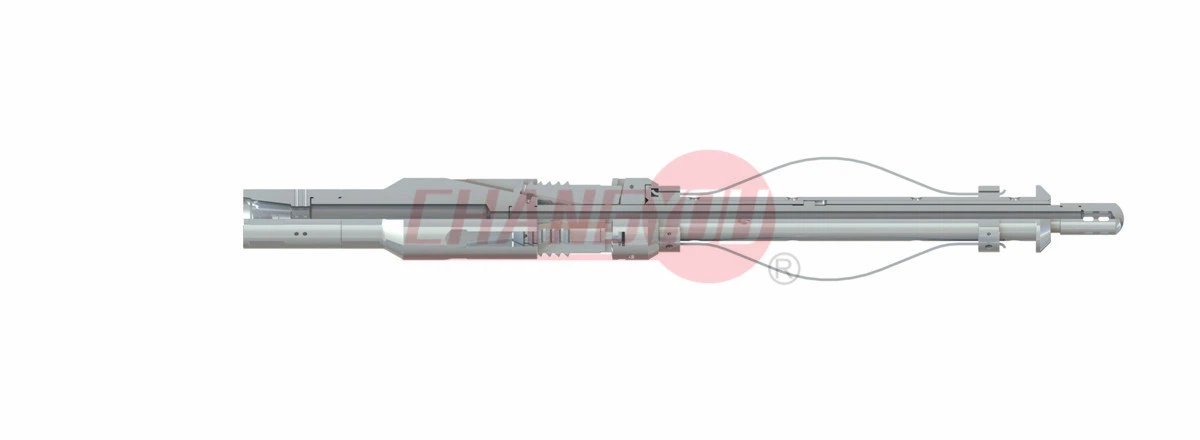

4 3/4 ″ hydraulic jar is a kind of tool for releasing jamming, which is mainly used in 5 ″ and 5 1/2 ″ open hole. When the string is stuck in the well, lift the whole string, and the tool will generate an upward shock force under the action of the delayed copper valve.

MFE Tester Valve

The MFE tester valve is a kind of conventional formation testing tool that realizes well opening and closing by raising and lowering pipe string. The downhole time is closed. After reaching the bottom of the well, gravity is applied through the drill string.

Openhole Bypass Valve

The open hole bypass valve is a set of tools installed under the test valve and operated by lifting and lowering. The delay mechanism of the open hole bypass valve is just opposite to that of the MFE tester.

Applications of Cased Hole Dst Tools

The hydraulic mechanism in the open hole DST tools allows for precise control over the jarring action. This enables operators to maintain greater control over the drill string, reducing the risk of accidents and improving overall safety during drilling operations.

With the ability to quickly release stuck drill strings, the open hole DST tools maximizes drilling efficiency. It minimizes downtime by rapidly overcoming obstructions and reducing the need for manual intervention, ultimately resulting in significant cost savings.

Deepwater drilling requires equipment that can withstand harsh conditions and deliver consistent performance. The open hole DST tools, with its robust construction and advanced hydraulic system, offers unparalleled reliability, ensuring uninterrupted drilling operations in the toughest environments.

Applications of Open Hole Dst Tools

● Stuck Pipe Recovery

In deepwater drilling, the drill string can often become stuck due to various factors like differential sticking or wellbore instability. The open hole DST tools plays a crucial role in recovering the stuck pipe, allowing operations to proceed without delays.

● Sidetracking Operations

Sidetracking involves creating a new borehole from an existing well. This technique is often employed in deepwater drilling to access additional reservoirs or mitigate wellbore problems. The open hole DST tools aids in the successful execution of sidetracking operations, ensuring accurate well placement and increased productivity.

● Casing Running

Installing casing strings is a critical step in deepwater drilling, as it provides integrity and stability to the wellbore. The open hole DST tools assists in casing running, providing controlled release and absorption of the jarring forces, minimizing the risk of casing damage during installation.

Precautions for Using Open Hole Dst Tools

Heavy pulling and jarring shall be carried out using the top drive/ kelly on the string. On those rare occasions where this is not possible, the elevator latch shall be secured by means of a rope or chain. Remove the kelly spinner (if possible) before any jarring with the kelly is done, to avoid damage.

When sustained jarring is done, the block-line shall be slipped at regular intervals to avoid permanent damage to the line at the cross-over points. The time interval between slipping depends on the intensity of the jarring.

If applicable consider closing a kelly cock in the string to prevent unwanted U-tubing, i.e.:

● To prevent back-flow as a result of spotting a pill in the annulus.

● To prevent losing to the annulus, a pill that is being purposely retained in the drill pipe.

Regularly check the derrick and lifting equipment for loose bolts etc. Ensure that the block-line cannot jump a sheave in the crown block.

Prior to jarring always mark the string position at the rotary table and simultaneously note the reading on the heave/tide indicator.

When jarring is carried out with a circulating sub in the string, check afterwards that the pin(s) of the sleeve have not sheared due to the jarring action. Avoid jarring with an overshot, as screwing back in is preferred.

Order Process

● First we discuss order details, production details by email or TM.

● Then we issue you an PI for your confirmation.

● You will be requested to do pr-epaid full payment or deposit before we go into production.

● After we get the deposit, we start to process the order. We usually need 7-15days if we don’t have the items in stock.

● Before production has been finished, we will contact you for shipment details, and the balance payment.

● After payment has been settled, we start to prepare the shipment for you.

Packaging and Shipping

|

Packaging |

Wooden box Or customized according to customer requirements |

|

Shipping |

We will help you to choose the best shipping way according to your detail requirements. By sea, by air, or by express, etc. |

Inspection Facilities

|

|

|

|

|

|

QC Flow Chart

Q: What does DST stand for in drilling?

A: A drill stem test (DST) is a procedure for isolating and testing the pressure, permeability and productive capacity of a geological formation during the drilling of a well.

Q: How to do flow check in drilling?

A: To perform a flow check, you need to stop the pumps and record the pump pressure and pit volume, close the annular preventer or upper pipe rams, and open the choke line to the choke manifold. Wait a few minutes to observe the drill pipe pressure and flow meter.

Q: How does the open hole DST tool differ from traditional drill stem testing tools?

A: Traditional drill stem testing tools usually use mechanical packers, while modern open hole DST tools are more likely to use inflatable packers. Inflatable packers have better sealing performance and adaptability, and can more effectively isolate the test layer section.

Q: How does the open hole DST tool work?

A: The open hole DST tool uses a drill pipe to deliver the test tool to the predetermined well section, and then uses an inflatable packer to isolate the test layer section. Next, the reservoir fluid flows into the test tool by reducing the well pressure, so that the fluid properties and production capacity can be measured.

Q: How to ensure the accuracy and reliability of open hole DST tools?

A: Ensuring the accuracy and reliability of open hole DST tools requires regular maintenance and calibration, and strict compliance with operating procedures during use.

Q: How does the open hole DST tool ensure safety during the test process?

A: During the test process, it is necessary to strictly abide by the safety operating procedures to ensure the safety of personnel and equipment. At the same time, the test tool needs to be monitored and controlled in real time to prevent unexpected situations.

As one of the most professional open hole dst tools manufacturers and suppliers in China, we're featured by quality products and competitive price. Please rest assured to buy high-grade open hole dst tools in stock here from our factory. Contact us for customized service.